UNIVERSAL MILLING MACHINE

Description

This series of universal milling machines is a model of multifunctional machine tools, with a very high cost performance.

The performance of metal processing is very superior too.

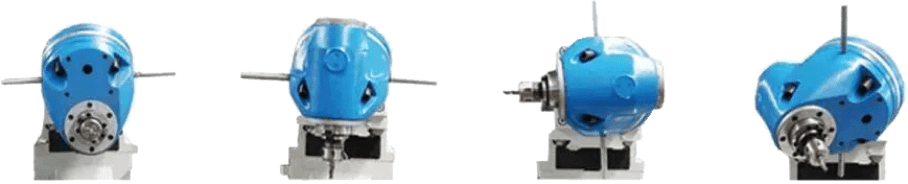

From a price point of view, when you buy this universal milling machine, equivalent to the purchase of 4 kinds of milling machine:

a vertical milling machine, a horizontal milling machine, a ram type milling machine, a rotary head milling machine which milling head can swivel 360 degrees, effectively reduce your procurement costs.In terms of performance, compared to ordinary milling machines,

this series of universal milling machines have better rigidity and stability, cutting more.

Main function introduction

Universal milling machine is a machine tool with milling cutter for milling process.

The spindle drives the milling cutter to rotate, and the lead screw drives the worktable to

move left and right, up and down, to process the required shape.

Milling machine processing range is very wide, can process horizontal plane, vertical surface,

keyway, T-groove, dovetail groove, gear, spline shaft, sprocket, spiral surface and so on.

Through the rotary milling head, multi angle machining can be carried out.

When the horizontal milling cutter bar is installed on the main shaft, horizontal milling

can also be carried out, and multiple saw blade milling cutters can be clamped at one time. It’s very efficient.

Universal milling machine

for sale, image, specification

Universal Milling Machine WN736

Table size (mm)

1500*360

Table travel

900*320*450

Main motor (kw)

4kw

Swivel angle of milling head

±360°

Universal Milling Machine WN736A

Table size (mm)

1600*360

Table travel

900*300*390

Main motor (kw)

4kw

Swivel angle of milling head

±360°

Universal Milling Machine WN736C

Table size (mm)

1600*320

Table travel

800*310*420

Main motor (kw)

7.5kw

Swivel angle of milling head

±360°

Universal Milling Machine WN736D

Table size (mm)

2000*400

Table travel

1200*315*385

Main motor (kw)

11kw

Swivel angle of milling head

±360°

Universal Milling Machine XN26

Table size (mm)

1200*280

Table travel

650*200*450

Main motor (kw)

2.2kw

Swivel angle of milling head

±360°

Universal Milling Machine XN32

Table size (mm)

1500*320

Table travel

800*300*450

Main motor (kw)

3kw

Swivel angle of milling head

±360°

Universal Turret Milling Machine 4v

Table size (mm)

1270*254

X/Y/Z table travel(mm)

800*310*420

Spindle taper

R8

Universal Turret Milling Machine 5V

Table size (mm)

1370*305

X/Y/Z table travel(mm)

810*410*450

Spindle taper

NT40

Universal Turret Milling Machine XTR36

Table size (mm)

1600*360

X/Y/Z table travel(mm)

900*300*350

Swivel head angle

±45°

Spindle taper

NT40

Universal Drilling Milling Machine ZX6350A

Table size (mm)

1200*280

X/Y/Z table travel(mm)

600*310*400

Spindle taper

MT.4

Universal Drilling Milling Machine ZX6350C

Table size (mm)

1200*280

X/Y/Z table travel(mm)

600*310*400

Spindle taper

MT.4

Universal Drilling Milling Machine ZX6350D

Table size (mm)

1200*280

X/Y/Z table travel(mm)

600*310*400

Spindle taper

MT.4

Universal Drilling Milling Machine ZX7550C

Table size (mm)

1000*240

X/Y/Z table travel(mm)

500*230*350

Universal Drilling Milling Machine ZX7550CW

Table size (mm)

1000*240

X/Y/Z table travel(mm)

500*230*350

Universal Vertical Milling Machine V32

Table size (mm)

1320*320

X/Y/Z table travel(mm)

700*255*350

Spindle taper

ISO50

Universal Vertical Milling Machine V32

Table size (mm)

1700*400

X/Y/Z table travel(mm)

900*315*385

Spindle taper

ISO50

Feature of universal milling machine

CE certification

The milling head can swivel 360 degrees

Milling head has strong rigidity and good stability

Two – axis mechanical cutter, automatic feed

Z-axis electric lift

Accessories optional: universal indexing head, rotary table, digital display (DRO), horizontal milling rod

Universal dividing head and X axis lead screw can realize the linkage , to do screw machining

What is universal milling machine?

Parts, Structure

1 Base

2 Handwheel

3 The workbench

4 Universal rotary milling head

5 Horizontal spindle

6 Speed change handle

7 Vertical column

Universal milling machine production process (Quality control)

01

Through the three-dimensional software finite element analysis, the equipment structure is checked and optimized to ensure the stability of the equipment structure.

02

Aging treatment is carried out

to eliminate internal stress

and improve stability

03

Milling the parts, boring the boring machine, milling the worktable plane with the gantry milling machine, scraping and grinding the joint surface of the machine tool manually, and checking the quality of the purchased components.

04

Assemble according to the process installation drawing, and measure the accuracy

with measuring tools.

05

Linking electrical appliances

and operation buttons.

06

After the completion of the cutting test,

and the accuracy measurement of

the whole machine

HOW TO OPERATION UNIVERSAL MILLING MACHINE

Ensure that the foundation of the machine tool is stable and level.

Ensure that the foundation of the machine tool is stable and level.

Check whether the power supply and the main power supply voltage of the equipment match, and connect the power supply.

Check whether the power supply and the main power supply voltage of the equipment match, and connect the power supply.

Check whether the lubricating parts are lubricated according to the lubrication diagram and the marks on the machine toolInstall the tool and manually adjust the worktable to the required position, Rotate the milling head to the required angle.

Check whether the lubricating parts are lubricated according to the lubrication diagram and the marks on the machine toolInstall the tool and manually adjust the worktable to the required position, Rotate the milling head to the required angle.

The angle calculation table can refer to the manual.

The angle calculation table can refer to the manual.

The transmission mechanism of the spindle is in the ram.

The transmission mechanism of the spindle is in the ram.

On the left or right of the ram, there are three shift levers.

On the left or right of the ram, there are three shift levers.

To change speed, adjust the shift levers to get different spindle speed. Note: speed should be changed when the machine is stopped.

To change speed, adjust the shift levers to get different spindle speed. Note: speed should be changed when the machine is stopped.

In horizontal milling, install cutter onto the horizontal spindle.

In horizontal milling, install cutter onto the horizontal spindle.

The machine is also equipped with horizontal milling trestle and cutter bar to realize different milling functions.In milling,

The machine is also equipped with horizontal milling trestle and cutter bar to realize different milling functions.In milling,

try to reduce hanging extrusion of the ram and the cutter.

When milling after adjusting the position, hold firmly all the moving pairs that are not necessary to move

When milling after adjusting the position, hold firmly all the moving pairs that are not necessary to move

(such as the ram, longitudinal direction and transverse direction) to improve the stiffness of the machine.

The holding force should not be too big to avoid deformation.

The holding force should not be too big to avoid deformation.

The machine has lumped button station. It is equipped with emergency button, which can be pressed down immediately

The machine has lumped button station. It is equipped with emergency button, which can be pressed down immediately

when abnormal condition appears.

There is also a power starting switch. After troubleshooting, to start it again, first turn the emergency button clockwise for an angle to reset it, then press down the power switch to start the machine.

There is also a power starting switch. After troubleshooting, to start it again, first turn the emergency button clockwise for an angle to reset it, then press down the power switch to start the machine.